It’s true oil samples can find an issue way ahead of the obvious which means it’s usually too late to save an engine from catastrophic failure. If the driver comes to me with an engine noise complaint I always hope it’s a loose charge air clamp or fan belt. The difference between finding engine wear right away with an oil sample report compared to waiting until something pops is a major repair bill.

I strongly believe in taking an oil sample every major service and sending it out to the lab for analysis because every metal and chemical under the sun gets checked for high levels. Something like high fuel dilution in a report indicates there is a possibility of a bad injector or the high pressure fuel pump has a bad seal.

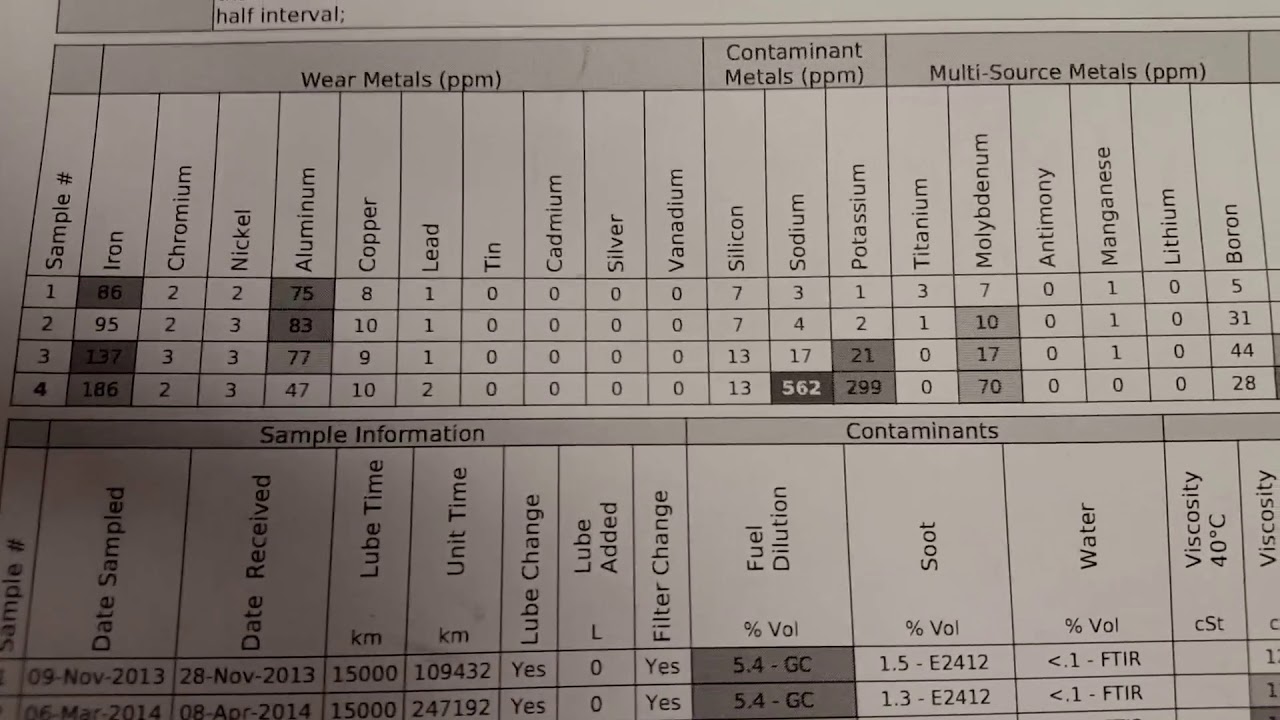

The only other way without a report is the oil level in the crankcase is over the full mark. By that time it may be too late. The viscosity is reduced leading to a lot more wear on the engine. The oil change intervals in our fleet are every 15,000 km which means there is about a 3 to 4 month period on average between oil changes. A lot of reports have returned with aluminum, steel and copper which doesn’t sound good but regular wear is constant on a hard working diesel engine.

The video pointed out the high coolant content in the oil which is is serious. The only component that fails on a regular basis that is in contact with coolant is the EGR cooler. the best method to confirm if the EGR cooler is leaking coolant is to do a pressure test. The two coolant lines that are hooked into the engine cooling system can be set up with an air regulator.

Thirty psi of air will tell if the EGR core is leaking. These coolers cost a lot of money so it’s nice to be double sure it’s failed. The other option would be the head gasket but that hasn’t been the case with our engines. Once the EGR cooler is replaced along with the engine oil our bus is back in business. The diesel engine in question is the Navistar MaxxForce DT. The engine in the video was very close to being over the warranty period but with the oil sample giving us the heads up we sent this bus to the dealer in time.