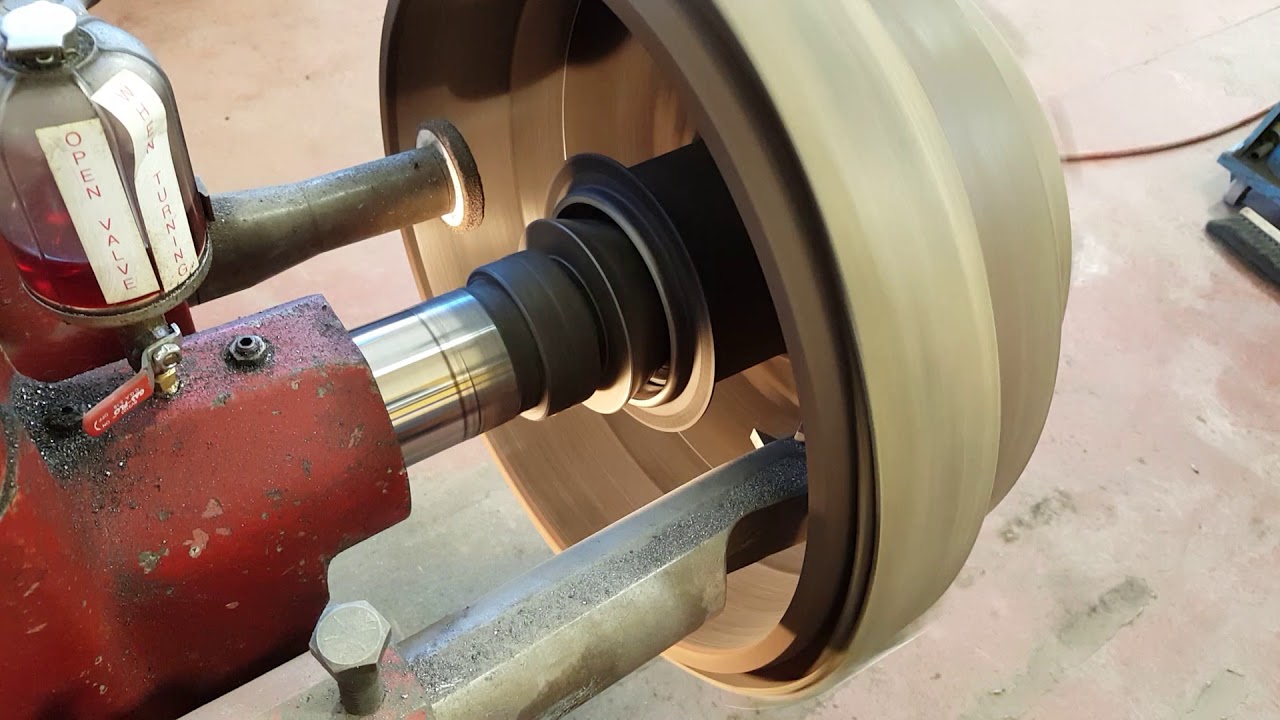

In this day and age speed is everything in all customer service categories. We have drive thru fast food joints, self check out at the markets, bank machines and everything else in the service industry that’s designed for speed. This video of a brake lathe machining a drum is slow as it can get compared to throwing on new parts and kicking out the vehicle. That is today’s standard… replace the brake shoes, drums, hardware kit and you’re done.

What about the imperfect brake parts (especially brake drums) that I know from experience are a common problem. It takes an average of 25 to 30 thousandths of machining on aftermarket brake drums to get them true. The brake shoes are not perfect either and take a few cuts with the shoe lathe to get them even. I actually can not believe how out of round the drums and linings are from vendors. When they are installed off of the shelve the contact may start at 30% and eventually wear in after regular braking.

I understand why a retail shop will not use this equipment for every brake job due to the competition and time frame. Customers do not want to pay for an extra 3 or 4 hours labor to refine their brake to drum contact. For us we only use machining for squealing, chattering or pulling brakes. Our fleet can definitely afford to take the extra time to cure a braking condition. We could change the brakes and see how it goes but most times the shoes and drums have a lot of life left so hundreds of dollars can be saved on parts.

School bus brake problems must be looked at immediately and repaired. Squealing brakes turn heads so when the public notices the noise is coming from a school bus the issue is accentuated. There are times that our shop gets a phone call from a parent or a concerned citizen. Pulling front brakes especially in the winter time is a concern obviously because of the control lost while coming to a stop or driving on the highway. Machining is the ultimate solution after the brake adjustment is checked out.

Any kind of brake system is engineered from the factory to stop the vehicle under certain conditions. Those engineering specs go out the window when the brake drum gets glazed or the brake lining wears unevenly. It’s up to the owner/operator and maintenance shop to keep on top of the issues.