This particular problem is on a 2009 Cummins ISC diesel engine. This model is an inline 6 8.3 Liter running in a Thomas HDX pusher school bus. The amber light presented itself on a field trip but did not cause any running problems mainly because it was an emission code. When the onboard computer does not see the proper parameter from a sensor it tells the operator and us in the shop there is a problem and it’s not going away until it gets fixed.

The amber warning is just that… a warning. It’s saying the engine is safe to operate but it will not be as efficient. Code 1899 involves the EGR differential pressure sensor. It monitors the exhaust pressures in the intake system and helps adjust the EGR valve to the best position for optimum emission control. Like all sensors there are 3 wires communicating with the ECM, the 5 volt reference, ground and sensor signal.

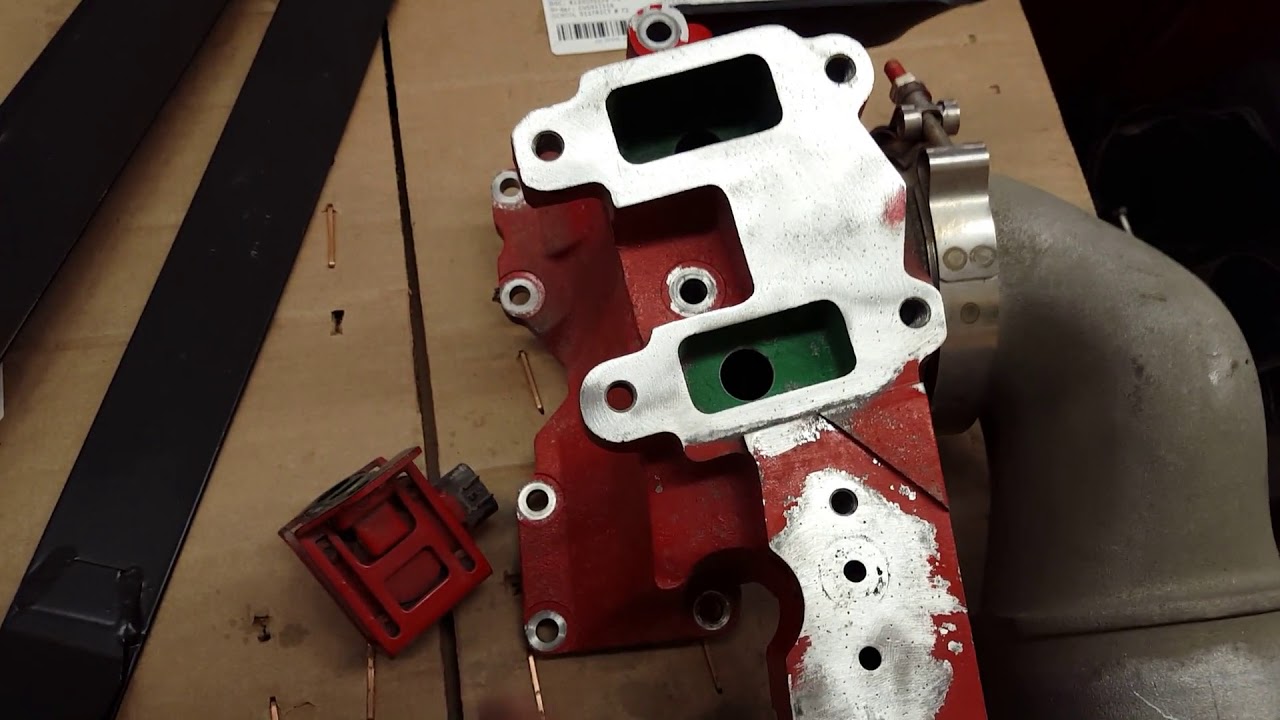

This was the first step we took checking for proper ground, voltage and sensor signal. We cheated a bit and robbed a sensor we knew was in good working order and installed it on our coded engine to see if the code would go away. That didn’t happen so according to the troubleshooting procedure from the Insite Lite diagnostic software the next step was to remove the intake housing that the EGR valve bolts to and check the 2 drilled passages that connect to the pressure differential sensor.

Sure enough one of the orifices was packed solid with carbon. It took some time in our parts washer to get some heat into the housing and loosen up the sludge build up that was blocking the flow of exhaust gas to the sensor. Once that was accomplished we replaced the gaskets and reassembled the housing and EGR valve to the engine. The road test revealed no more code which is a very satisfying feeling.

The total cost of this job was $36.00 for gaskets. That is amazing considering some of the prices for diesel engine parts these days. I really like Cummins diesel engines for their high quality design and minimal problems. Cummins is a very aggressive company who are always researching and keeping up with the demands from the EPA and fussy customers like us.

Our 2014 and 2015 ISB diesel engines use diesel exhaust fluid that we keep on hand by the drum. It feeds the SCR and reduces emissions even lower and compliments the DPF system. If I had my way our entire fleet would be powered by Cummins which exceed by far the reliability of our other diesel engines in the fleet.