In 2013 we purchased eight International school buses with the MaxxForce 7 V-8 diesel engine. Knowing now what we didn’t know then would have effected our decision to go with these models. Out of the 8 engines 4 of them had to be replaced due to excessive low compression. There is no way to rebuild these engines so the expense is through the roof with the cost of a long block. Luckily all of the engine replacements were covered under warranty. Several diesel particulate filters failed as well with black smoke out the tail pipe which was the indicator of complete DPF failure.

This video shows one of the engines replaced under warranty which unfortunately ended up losing coolant because of engine compression leaking in to the cooling system and blowing coolant out the reservoir. The first time it happened the bus was a couple of miles from the shop with coolant low enough to trigger the red stop engine light. One way to get around this situation is to top the coolant back up to the normal level and remove the radiator cap. This allows the engine to run without pressure to prevent coolant loss enabling us to drive the bus back to the shop.

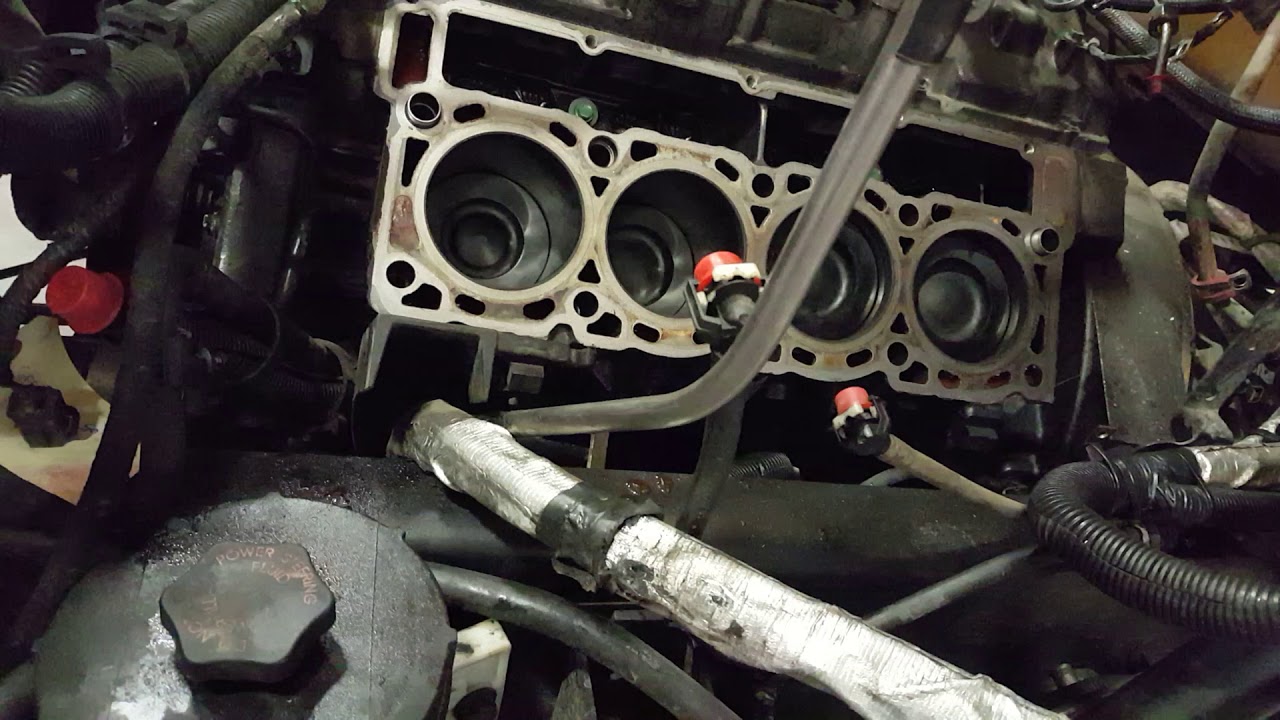

Then we confirm compression in the coolant by checking the operating pressure removing the factory radiator cap and installing a cap with a pressure gauge and seeing what happens on a road test. In this case the pressure climbed to 25 psi pulling a hill under load. Normally the operating pressure is around 8 psi with a 15 psi radiator cap. We notified the dealer and sent them the bus …they proceeded to replace the engine which brings us to the present. The heads have been removed and will most likely be replaced with new head gaskets which hopefully will fix the problem.

This scenario is not typical with a school bus that runs 4 hours a day hauling students 9 months a year. Our garage updated the servicing schedule to replace engine oil sooner removing damaging engine contaminants caused by emissions. The inconvenience of having a bus down for long periods of time means using spare buses that are high milers and older which increase the risk of a break down. After this engine is repaired under warranty we are on our own dealing with future problems on all eight of these buses. There have been no changes in the engineering with these engines so it comes down to keeping a close eye on them to hopefully prevent any engine issues which will be repaired on our dime.