I’ve been asked several times over the last 20 years if we get the Summer off. I said no you’re thinking of the teachers and bus drivers. The Summer is like a breath of fresh air for us with 2 months to get caught up and have some time to find ways to prevent regular problems we experience through the year from re-occurring. The problems are not major issues just hit and miss aggravating stuff that takes up valuable time and usually when the bus is needed the most.

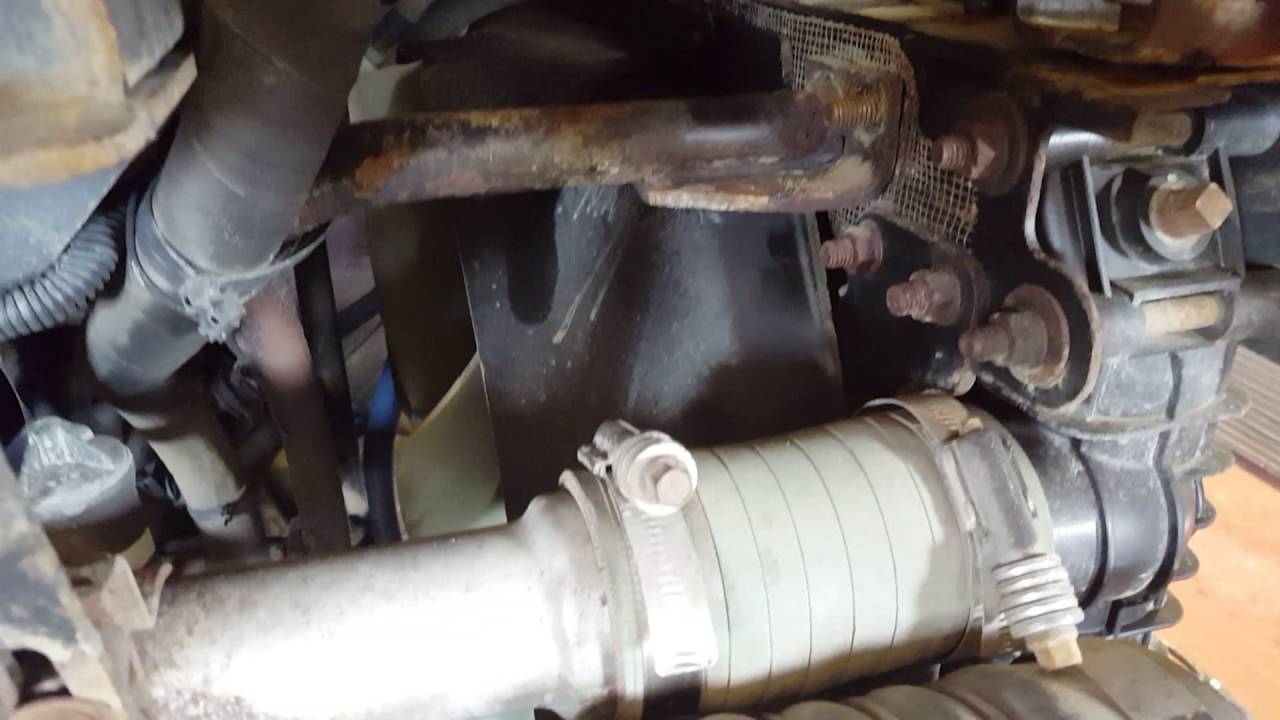

For instance our Thomas pusher buses (rear engine) have a transversely mounted radiator and charge air cooler. In other words it’s mounted sideways on the passenger side of the engine compartment. To compensate for this there is a fan drive that is hydraulically driven by the power steering pump and regulated depending on engine coolant and charge air temperatures. When the coolant temperature reaches 200 degrees the fan kicks in full blast. Otherwise it holds back fan RPMs to save horsepower.

The problem we have is debris and dirt that collects on the radiator core on the street side of the core and in between the radiator and charge air cooler. It eventually plugs up a good 30 percent of the core area and on a hot day the engine coolant temperature climbs up to 220 degrees. This triggers the engine warning and shut down system. That’s a great system to have in place to protect the engine but I don’t like it when it happens during a bus run. The scenario is usually when the bus is climbing a grade and the ambient temperature is around 25 to 30 Celsius.

What we have planned for our pusher buses is on a regular basis clean out the radiator core without having to remove it from the chassis. There is very little room between the charge air cooler and the radiator because of the way they are sandwiched together to get the engine fan air flow simultaneously. The way to clean out the core is to blow through it with pressure air or a pressure washer from the fan blade side. Once the debris is knocked off hit it again with the steam cleaner.

The street side of the radiator has to be steam cleaned as well but the charge air cooler is mounted so close to get the necessary air flow from the fan that it’s tough to get to the radiator core. We have been steam cleaning through the charge air cooler hoping to get enough pressure contacting the rad core. You can’t see the results of your cleaning so that’s why hitting it with pressure from the fan side would help.

This is just theory right now since we don’t have a specific tool designed for this purpose. We need to reach into the fan shroud between the fan blades and move up and down along the radiator core. An air blow gun could be modified with lots of flexibility attached to a coiled ¼ inch plastic air line. Before the Summer is out we’ll have something in our hands to get this operation done and strike off another pesky problem. Getting the rad cores on all of our pusher buses without disassembly would save a lot of time.